Key facts

- Project duration: 01/01/2022 – 31/12/2024

- Funding budget: 3.145.371 €

- TRL at project start: 5 (Technology validated in relevant environment)

- TRL at project end: 7 (System prototype demonstration in operational environment)

About VALORE

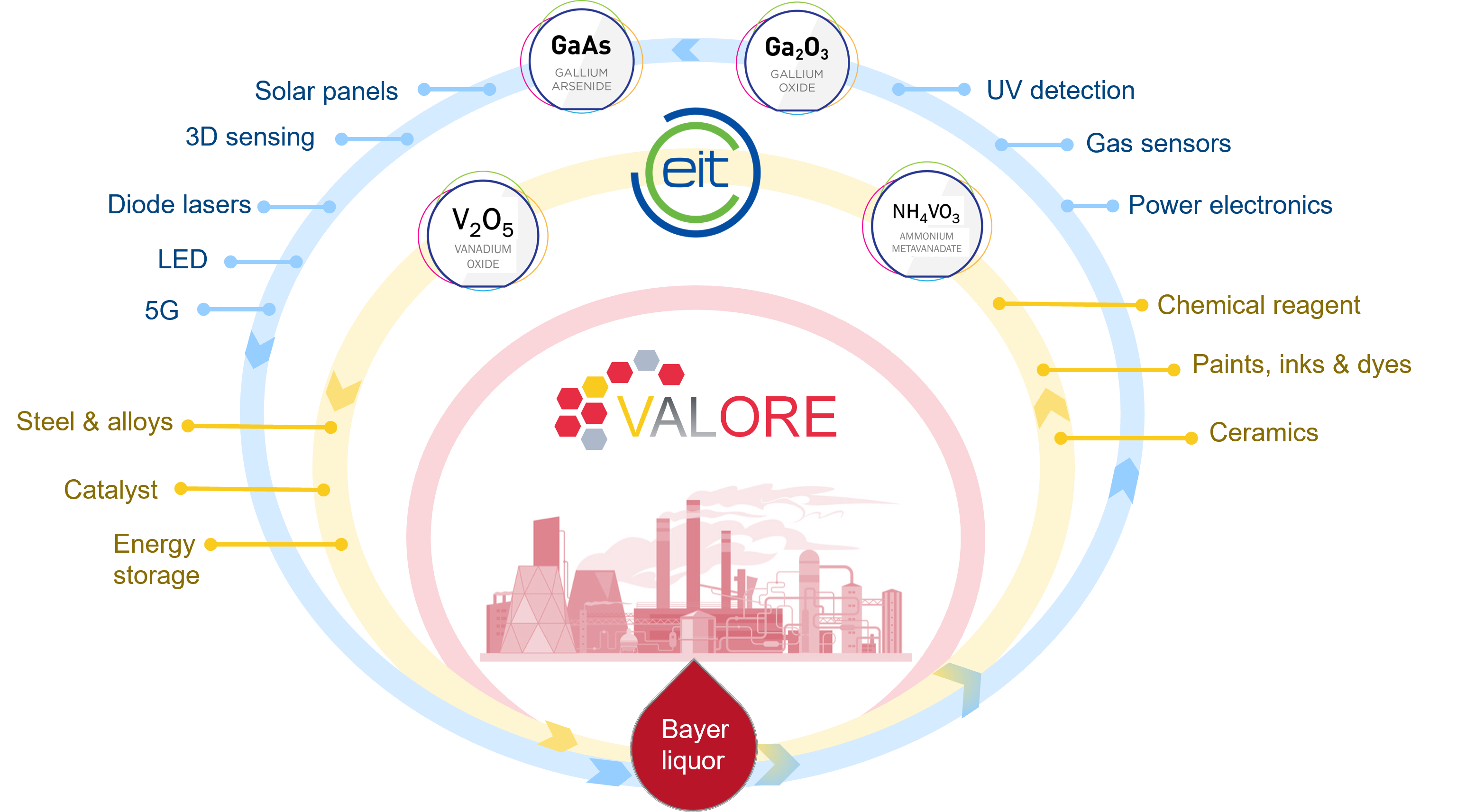

VALORE will upscale a novel process for the recovery of vanadium (V) and gallium (Ga) as by-products from an alumina refinery. Bayer Liquor from the aluminium industry is the main source for the production of Ga today. Even though, the Bayer liquor can also contain high concentrations of V, it is not yet recovered as by-product. Moreover, the presence of V in the liquor hampers the recovery of Ga since current technologies co-extract V and Ga simultaneously making it challenging to refine the Ga and V mixture.

By the selective recovery of V from the Bayer liquor, prior to Ga extraction, VALORE will solve two major problems simultaneously:

- tapping into a new source of V supply and

- making Ga extraction from high-V Bayer liquor more economically viable and environmentally friendly.

V is considered as a short-resource metal and with high political risk (Europe is depending for 100% on V imports). V is critical for the development of green technologies and renewable energy production and storage (e.g. V batteries). Also the production capacity of Ga is limited in Europe. Ga is a key element for the production of 5G applications (smartphones, wireless networks).

The VALORE project will bring the innovation to an industrial relevant level (TRL7) by connecting players in the whole material value chain: from processing (MYTILINEOS, MEAB) over production (BASF, VITO) and recycling (VITO, KTH). MEAB will engineer a V/Ga extraction pilot in an industrial alumina refinery (MYTILINEOS) integrating the new sorbent developed (by VITO) and produced at pilot scale (by BASF). KTH will purify the recovered V and refine to meet the requirements for its use in clean power applications.

Objectives

- Develop hydrometallurgical process for recovery of V and Ga as by-products from an alumina refinery based on the ion-exchange material showing superior selectivity and stability.

- Pilot scale production will be done in an industrial environment at MYTILINEOS.

The VALORE solution can overcome the 2 main challenges associated with the state-of-the-art technology to recover Ga from Bayer liquor.

The installation of a Vanadium extraction unit upstream of a Gallium extraction unit will increase the Gallium extraction efficiency. Up to 15% savings in extractants, service and maintenance time are estimated. In addition to the revenues generated from the valorization of the by-products, the extraction of Vanadium from spent Bayer liquor is also advantageous for the productivity of the refinery itself. Reduced Vanadium concentrations have a positive effect on the precipitation of Alumina. Moreover, Vanadium extraction reduces its risk for negative environmental impact. The concept of in-line Vanadium and Gallium extraction added to Alumina production can be transferred to European Alumina refineries to reduce import risks of these strategic elements.

VALORE process - Gallium and Vanadium products and applications