1st International Circular Hydrometallurgy Symposium – ICHS 2024

VALORE PROJECT – VANADIUM AND GALLIUM RECOVERY FROM BAYER LIQUOR

Abstract:

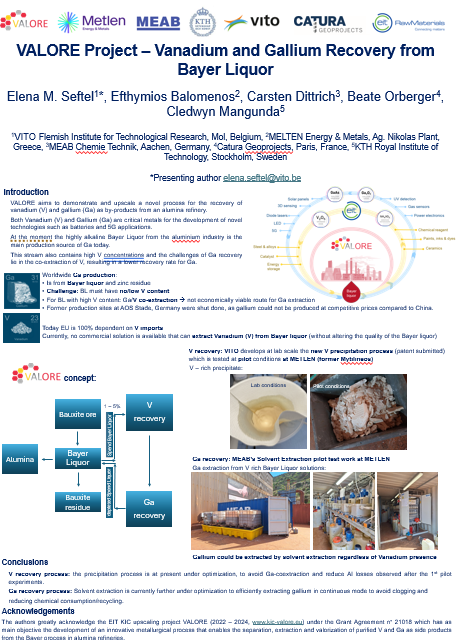

VALORE is upscaling a novel process for the recovery of vanadium (V) and gallium (Ga) as by-products from an alumina refinery. The typical process for gallium production is the extraction during the Bayer-process in the production of aluminium, since bauxite, the feed-material for the process, contains up to 0.008 % gallium. Therefore 90 % of the gallium produced worldwide is generated from the Bayer process.

Both vanadium (V) and Gallium (Ga) are critical metals for the development of novel technologies such as batteries and 5G applications. However, the production capacity of both metals in Europe is limited to non-existent. At the moment the highly alkaline Bayer Liquor from the aluminium industry is the main production source of Ga today. This stream also contains high V concentrations and the challenges of gallium recovery lie in the co-extraction of vanadium, resulting in a lower recovery rate for gallium.

The innovative metallurgical process is under demonstration at pilot scale (TRL7) on the site of the MYTILINEOS Alumina refinery in Agios Nikolaos (Greece).

At present, Gallium extraction piloting is performed at the MYTILINEOS plant. Vanadium extraction is also under preparation for piloting in V/Ga extraction pilot, thus sufficient gallium and vanadium concentrates will be available by Q3/2024 for refining tests.

The aim is to generate AMV or V2O5 as well as GaCl3, further to be precipitated as Ga(OH)3 of GaAs.